Autres types d'audits

Tests d'aspiration, tests bactériologiques, contrôles HACCP, contrôles de désinfection des points de contact.

Contactez-nousLa Qualipso Suite permet de réaliser toute une série d'audits complémentaires : tests d'aspiration, tests bactériologiques, contrôles HACCP, contrôles de désinfection des points de contacts

A tout moment de votre contrat. Ces audits sont habituellement réalisés par les équipes de QUALIPSO.

Tests d'aspiration des sols textiles

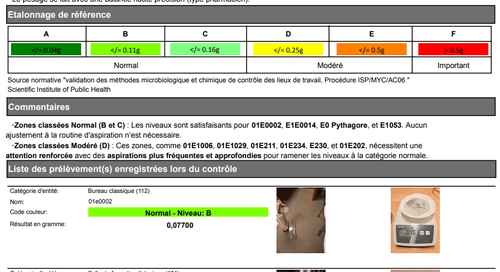

Le module « Aspiration » permet de réaliser des tests concernant la bonne aspiration des surfaces textiles.

Ces tests permettent de mesurer l'efficacité des équipements et des techniques de nettoyage utilisés, en vérifiant que les moquettes et tapis sont bien débarrassés des particules et résidus incrustés.

Le principe est facile : un(e) employé(e) de QUALIPSO viendra aspirer une/des zone(s) test de 1 m² pendant 1 minute avec un aspirateur étalon. Ensuite, à l'aide d'une balance de précision, il/elle pèsera la poussière récoltée et comparera le résultat à une échelle de référence.

En identifiant les zones nécessitant des améliorations, les tests d'aspiration assurent un environnement intérieur plus sain et agréable tout en prolongeant la durée de vie des textiles.

Tests bactériologiques

Le module « Bactério » permet de réaliser le suivi de contrôles bactériologiques.

Effectuer des tests bactériologiques dans les entreprises et les lieux accessibles au public est essentiel pour assurer un environnement sain et protéger la santé des usagers.

Ces tests permettent de détecter et quantifier la présence de micro-organismes potentiellement dangereux sur des surfaces fréquemment touchées, comme les frigos, les fontaines à eau ou les sanitaires, réduisant ainsi les risques de contamination croisée.

En fournissant une analyse objective de la propreté, ils permettent aux gestionnaires d’améliorer les protocoles de nettoyage et de désinfection de manière ciblée et efficace.

Dans des lieux très fréquentés comme les bureaux, les écoles, les hôpitaux ou les restaurants, les tests bactériologiques jouent un rôle clé dans la prévention des infections et la maîtrise de l'hygiène.

Contrôles HACCP

Réaliser des contrôles selon la méthode HACCP (*Hazard Analysis Critical Control Points*) est essentiel dans les secteurs où l'hygiène a un impact direct sur la sécurité alimentaire et la santé des consommateurs, et notamment dans la restauration et l'industrie alimentaire.

La méthode HACCP vise à identifier, évaluer et maîtriser les risques liés à l'hygiène, en ciblant spécifiquement les points critiques où une contamination pourrait survenir. En appliquant ces contrôles, les entreprises peuvent s'assurer que chaque étape de leur processus respecte des standards stricts pour éviter les risques de contamination croisée, de prolifération bactérienne et d’intoxications alimentaires.

Grâce aux contrôles HACCP, les entreprises renforcent la sécurité de leurs produits, assurent la conformité réglementaire et maintiennent la confiance des clients en leur garantissant un environnement sain et sécurisé.

Nos contrôles HACCP permettent au prestataire de catering de se préparer à un contrôle externe de l'AFSCA.

Contrôles de désinfection des points de contact

Les contrôles de désinfection des points de contact sont essentiels pour assurer la sécurité et la santé dans tout environnement, mais plus particulièrement dans les lieux à forte fréquentation comme les bureaux, les écoles, les hôpitaux, les commerces ou les transports en commun.

Ces points de contact, comme les poignées de porte, les interrupteurs, les rampes d'escalier ou les claviers d'ordinateurs, sont des vecteurs potentiels de transmission de germes, de virus et de bactéries. En effectuant des contrôles réguliers de leur désinfection, les entreprises peuvent garantir que ces zones à haut risque sont correctement entretenues et nettoyées, réduisant ainsi les risques de contamination croisée et de propagation d’infections.

Ces contrôles ont été essentiels durant la période Covid mais ils restent d'actualité dans tout environnement sensible.